|

| CROSSSQUARE |

|

| Here is the story of perfect customer-clockmaker cooperation |

|

| There was an empty place above the table on the beginning. And a request from customers to fill it sense and clockfully. |

|

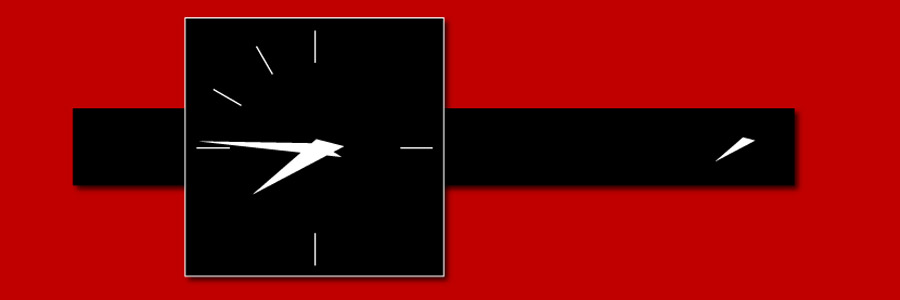

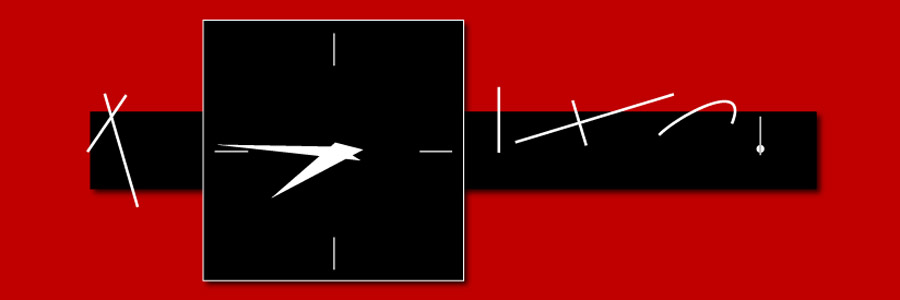

| Both sides agreed on a meeting. This meeting took place at clokmakerīs workshop. After creative and peacefull discussion was clockmaker asked to send some proposals. And he did. Hello I am sending you first proposals. Let me know if we are heading the right direction. |

|

|

|

|

|

|

|

|

|

|

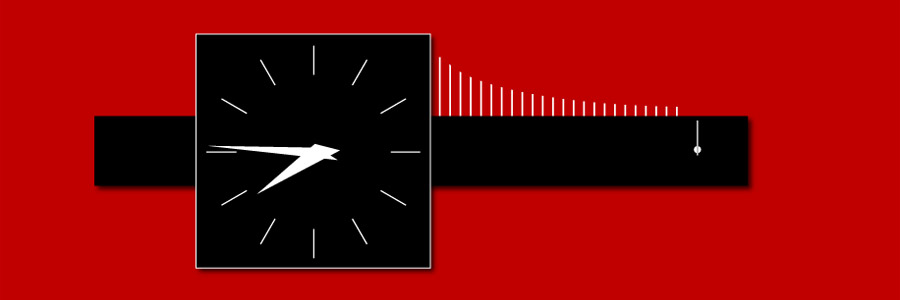

| Customers answered Hello You really hurried up. We did not expect such quick response :). We like the proposal no.4 most. But can you use the clock face from no.3? |

|

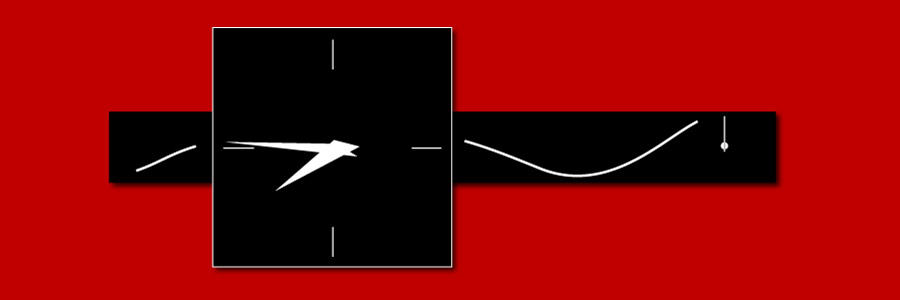

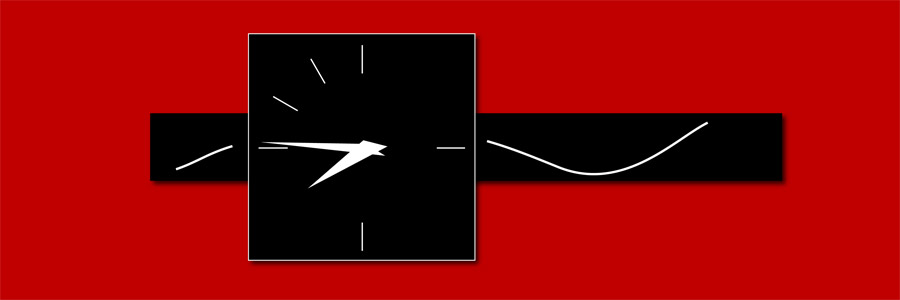

| And clockmaker again Good morning I guess some things are best to do at once after discussion. Even if it is hard and one can not make it every time:) I was lucky yesterday I guess. I am sending possible final solution. I would ask you please for exact size of the wall. |

|

|

|

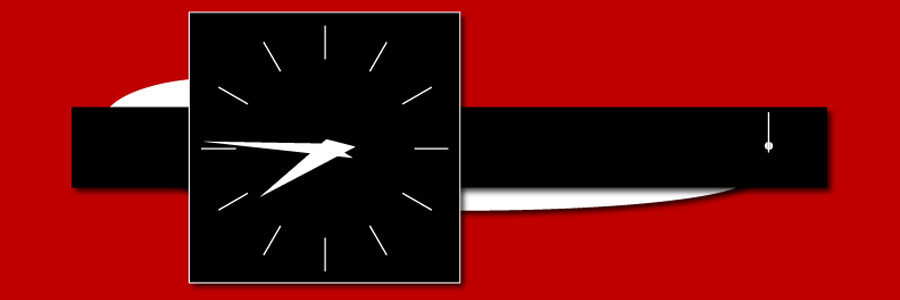

| Customers Hello You can consider this design as approved! We will measure the wall in the evening and send you exact proportions. |

|

| Clockmaker Thank you. I am happy we found the right solution :) Would be great for me if you can estimate the real length of clock (the long rectangular part). |

|

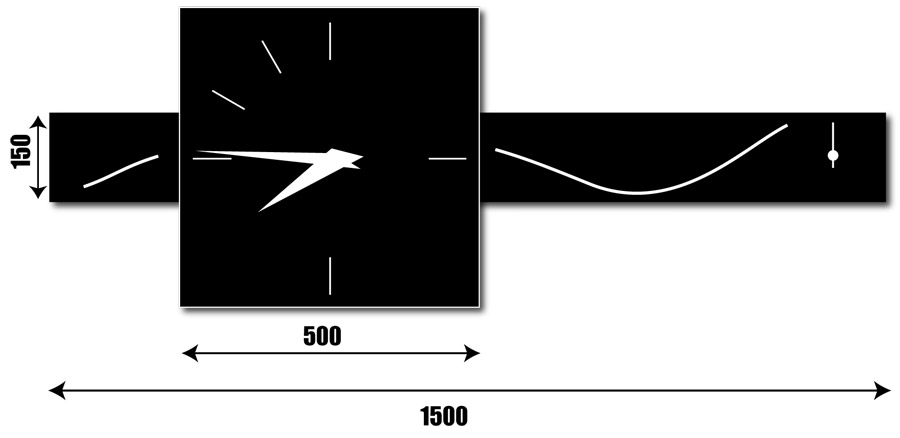

| Customers Good Evening we measured the wall and the lenght is 257cm. So the size of the clock could be : total lenght 150cm, size of clock face square 50x50cm (or 45 x 45, we will leave it on experts eye ;). |

|

| Clockmaker Hello I made little calculation and this is the result. I will start on this project soon and contact you for possible consultation if needed. |

|

|

|

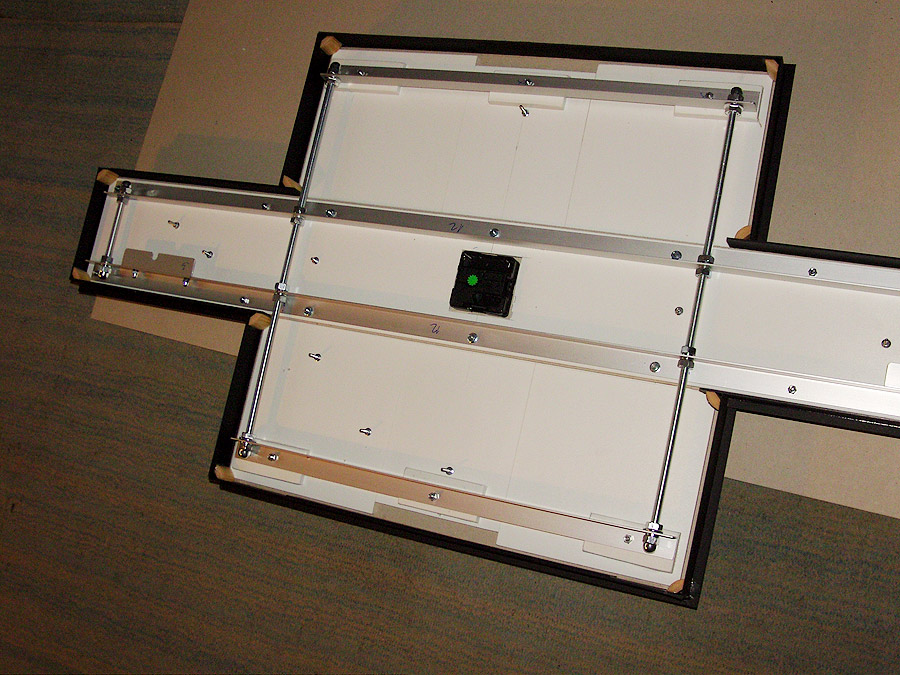

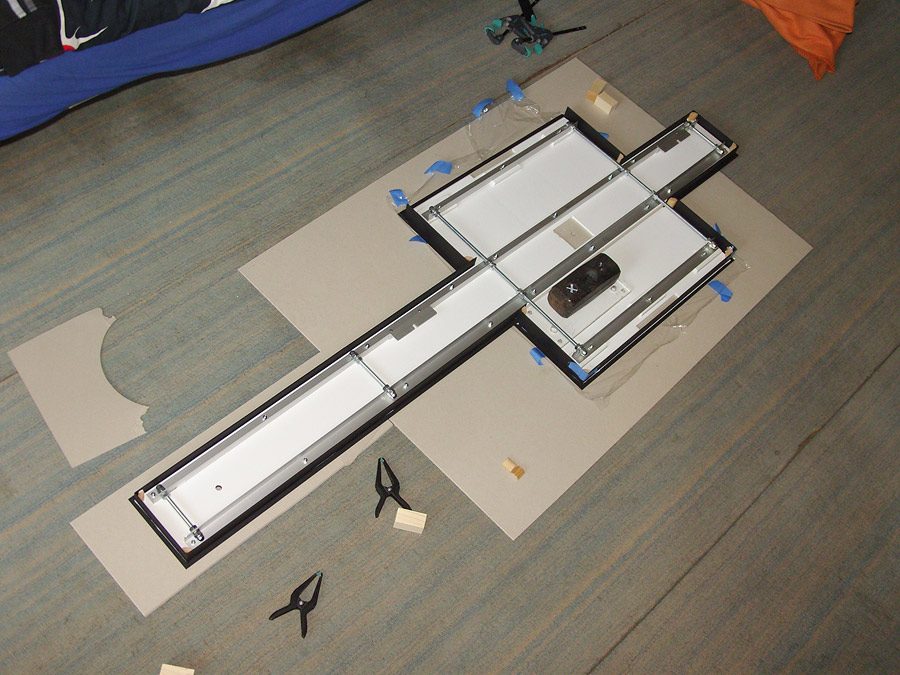

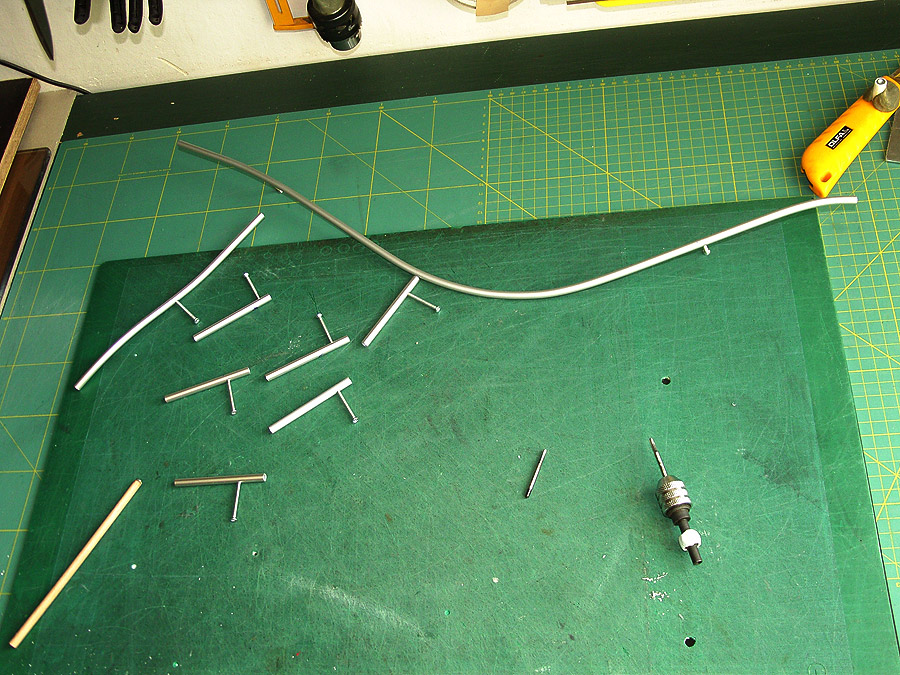

| First forethought - what kind of support construction will be used? And the winner is - flexible, solid and labourious combination of threading rods and aluminium profiles. |

|

|

|

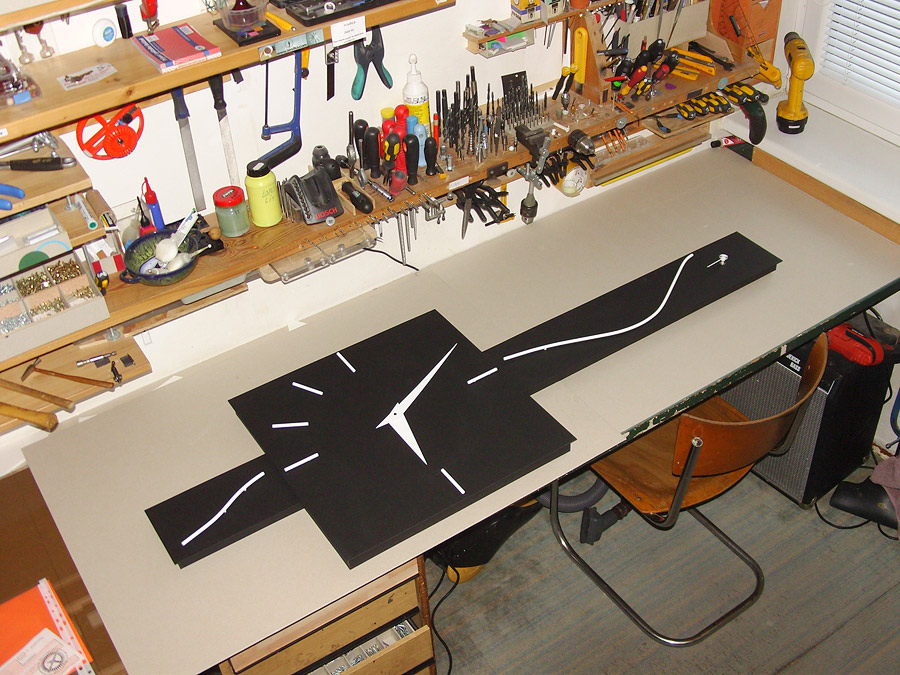

| (upper picture) Grid-like construction is made first. Then covered with plastic and cardboard sheets. These are attached to the framework with screws. A perspective front material is glued then on the base-frame. It is very thick special black paper in this case. Thanks to solid construction will the paper not deform. That little black square in the middle is a clock movement with strong torsion moment. It is better to use stronger clock movement because of longer clock hands. There is more work on this clock then expected ... Thanks to its size is not possible use the table and most of the work must be done on the floor. Carpet layers and floor makers will know what does it mean to go up and down all the time :) (bottom picture) |

|

|

| Making clock-face components is next. They could be just glued to the surface. But there is better way to do it. And of course more labourious :) Make a hole in the part, then thread and finally install a short piece of screw (with cut of head). This way you can fix all parts to the clock with a possibility to remove them if needed (for example a renewal of paint) and you can also set elements little above the surface of the clock which makes better plasticity effect. All segments are made of aluminium tubes. |

|

|

| And there is a final result resting on the workshop table. |

|

|

| Clockmaker is sending a message to customers: "Your clock is ready". Customers are satisfied, accept the price and promise to send a picture of clock in their final postion above the table. They keep their word and you can judge the drop-scene of whole action. |

|

| Based on true story (year of grace 2010) Donīt you wanna have a made-to-measure clock above your table (or somewhere else) as well? |

|